Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PRODUCT CATEGORIES

View:

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

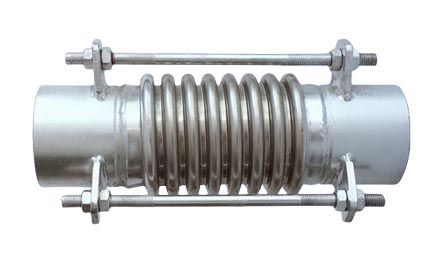

Welded Bellows Expansion Joint: Durable Solutions for High-Demand Pipeline SystemsThe welded bellows expansion joint stands as a paragon of durability and performance in industrial piping, offering a suite of advantages that set it apart in demanding environments. With inherent flexibility, fatigue resistance,...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Welded Type Bellow Expansion Joint: Efficient Compensation for Industrial Pipeline SystemsThe welded type bellow expansion joint—also known as a welded bellows compensator—emerges as an efficient and reliable pipeline connection component, engineered to balance flexibility, durability, and performance in diverse...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Heavy Duty Welded Expansion Joint: High-Strength Solution for Extreme Industrial PipingThe Heavy Duty Welded Expansion Joint stands as a robust cornerstone in high-pressure, high-stress industrial piping systems, engineered to withstand extreme conditions while accommodating thermal expansion, vibration, and...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Custom Exhaust Duct Expansion Joint: Tailored Flexibility for Industrial Ventilation Systems

The Custom Exhaust Duct Expansion Joint emerges as a precision-engineered solution for industrial ventilation systems, designed to address the unique challenges of exhaust ductwork—from thermal expansion and vibration...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

High-Temperature Welded Metal Bellows Expansion Joint: Durable Solution for Extreme Heat PipingThe High-Temperature Welded Metal Bellows Expansion Joint stands as a robust cornerstone in high-heat industrial piping systems, engineered to withstand extreme temperatures and pressure while accommodating thermal...

China Welded Type Bellow Expansion Joint Suppliers

Material

stainless steel 304, 316L, 321, etc.

Nominal diameter

DN32 - DN3000 mm

Product Detail

Application areas

The application areas of pipelines are very wide, mainly including municipal engineering, building water supply and drainage, industrial production, agricultural irrigation, new energy and other fields.

FAQ

Important things you should know

Home > Products > Bellow Expansion Joint > Welded Type Bellow Expansion Joint

Send Inquiry

Ms. Jing Wang

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.