Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PRODUCT CATEGORIES

View:

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

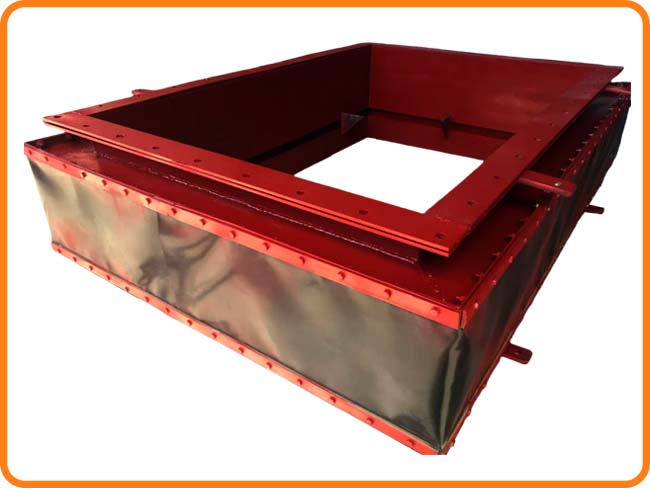

Fabric Expansion Joint: Flexible Non-Metallic Solution for Pipeline CompensationFabric expansion joint—also known as fabric bellow expansion joint—stands as a game-changing non metallic expansion joint fabric in modern pipeline systems, engineered to absorb thermal expansion, compensate for displacements, and enhance...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1

Certificate: ISO9001

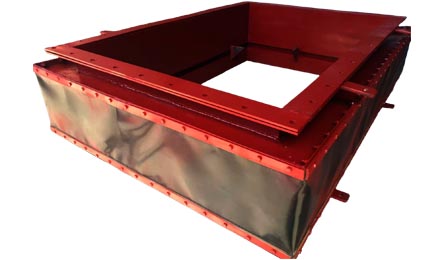

Industrial Silicone Coated Fabric Expansion Joint: Heat-Resistant Flexibility for Industrial PipingThe Industrial Silicone Coated Fabric Expansion Joint emerges as a specialized solution in industrial piping systems, blending the flexibility of fabric with the heat resistance of silicone to address thermal expansion,...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Fabric expansion joints: Multi-functional protection experts for non-metallic flexible compensationFabric Expansion Joint, also known as fiber compensator or non-metallic expansion joint, is a compensating device composed of materials such as fiber fabric and rubber. It holds an important position in complex pipeline...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Fabric expansion joints: Multi-functional guardians in the field of flexible compensationFabric Expansion Joint, as a flexible connection device specially designed to absorb pipeline expansion, contraction and displacement, plays a core role in compensating pipeline displacement caused by temperature changes, pressure...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1

Certificate: ISO9001

Fabric expansion joint: A high-temperature anti-corrosion solution with non-metallic flexible compensationFabric expansion joint, also known as fiber compensator, non-metallic expansion joint, and rectangular fabric fiber expansion joint, is a key component in pipeline systems that combines flexible compensation with...

China Fabric Expansion Joint Suppliers

Size

DN200-DN3600

Temperature

-200℃-400℃

Product Detail

Application areas

The application areas of pipelines are very wide, mainly including municipal engineering, building water supply and drainage, industrial production, agricultural irrigation, new energy and other fields.

FAQ

Important things you should know

Home > Products > Bellow Expansion Joint > Fabric Expansion Joint

Send Inquiry

Ms. Jing Wang

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.