Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PRODUCT CATEGORIES

View:

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

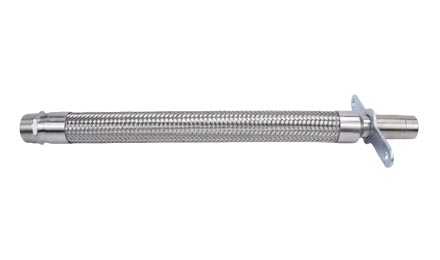

Threaded Connection Metal Hose: A Quality Choice with Comprehensive Service GuaranteeOur threaded connection metal hose is made from high-quality stainless steel, boasting excellent corrosion resistance and high-temperature resistance, making it a reliable choice in various harsh environments. Its unique corrugated...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Thread Connection Metal Hose: A Versatile Solution for Efficient Fluid Transmission and Connection Across Multiple ScenariosThread Connection Metal Hose, as a pipeline component integrating transmission and connection functions, features a metal corrugated tube as its core and threaded connectors as interfaces,...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Stainless Steel Bellows Hose: The Reliable Core of Flexible Pipeline TransmissionStainless Steel Bellows Hose stands out as a pivotal component in modern pipeline systems, celebrated for its exceptional combination of flexibility, corrosion resistance, and high-temperature tolerance. Crafted from premium stainless...

Brand: Xinhuagfeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1

Certificate: ISO9001

Stainless steel braided flexible hose: The choice for flexible connection and reliable transmission in industrial pipelinesStainless Steel Braided Flexible Hose, with its unique structural design and outstanding performance, has become the core component of flexible connections in industrial pipeline systems. It...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1

Certificate: ISO9001

Threaded Connection Metal Hose: Flexible Fluid Transmission Solution for Industrial SystemsThe metal hose stands as a versatile flexible pipe in industrial fluid and gas transmission, renowned for its pressure resistance, corrosion resistance, and flexibility. As a core Flexible Metal Hose variant, it finds...

China Thread Connection Metal Hose Suppliers

Application areas

industrial production, construction industry, agricultural irrigation and automobile manufacturing and repair

Features

high pressure resistance, high temperature resistance

Product Detail

Application areas

The application areas of pipelines are very wide, mainly including municipal engineering, building water supply and drainage, industrial production, agricultural irrigation, new energy and other fields.

FAQ

Important things you should know

Home > Products > Flexible Metal Hose > Thread Connection Metal Hose

Send Inquiry

Ms. Jing Wang

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.