Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

PRODUCT CATEGORIES

View:

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Analysis of the core of flexible connections in industrial pipelines: Flanged connection metal hoses and matching componentsIn the complex and changeable industrial piping system, Flexible Metal Hose has become an indispensable connection hub with its outstanding adaptability, and the Flan connection metal hose...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Key Factors for Selecting Flange Connection Metal Hose: Ensuring Compatibility and System ReliabilitySelecting the right Flange Connection Metal Hose is critical to ensuring the efficiency, safety, and longevity of piping systems across industries. The process requires careful consideration of working conditions,...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Flange Connection Metal Hose: Versatile Performance Across Industrial and Specialized Fields

The Flange Connection Metal Hose has cemented its 地位 as a cornerstone in diverse industrial and specialized fields, thanks to its exceptional performance in handling extreme conditions, reducing vibrations, and ensuring...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Flange Connection Metal Hose: Austenitic Stainless Steel-Driven Excellence in Extreme-Condition PipingAt the heart of the Flange Connection Metal Hose lies austenitic stainless steel, a material that elevates its performance to meet the most demanding industrial challenges. This core material ensures exceptional...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

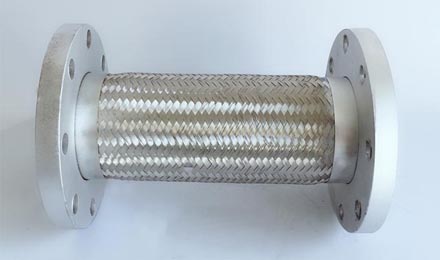

Flange Connection Metal Hose: High-Performance Core Component for Piping System Flexibility and ReliabilityIn piping systems, the Flange Connection Metal Hose with flanges on both sides stands as a pivotal component, delivering exceptional performance through its premium build and thoughtful design. Crafted from...

Brand: XinHuaFeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Flange Connection Metal Hose: Flexible and Reliable Piping Connection Solution for Diverse ScenariosFlange Connection Metal Hose is a widely used piping connection method that plays a crucial role in systems needing flexibility to handle installation errors, thermal expansion, or vibrations. Composed of a metal hose...

Brand: Xinhuafeng

Packaging: wooden case packing

Supply Ability: 100000 Piece/ per Month

Min. Order: 1 Piece/Pieces

Certificate: ISO9001

Flange Connection Metal Hose: Versatile Industrial Connection for Complex Piping SystemsThe flange connection metal hose—also known as the flange type metal hose—emerges as an efficient and versatile industrial connection solution, blending flexibility, durability, and stability to meet the demands of complex piping...

China Flange Connection Metal Hose Suppliers

Standard

DIN, JIS, ANSI, etc.

Length

Customized

Product Detail

Application areas

The application areas of pipelines are very wide, mainly including municipal engineering, building water supply and drainage, industrial production, agricultural irrigation, new energy and other fields.

FAQ

Important things you should know

Home > Products > Flexible Metal Hose > Flange Connection Metal Hose

Send Inquiry

Ms. Jing Wang

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.